The industrial landscape is undergoing a profound transformation driven by advances in connectivity, digital technologies, and data analytics. At the heart of this transformation lies the industrial internet of things (IIoT)—a technological revolution that is redefining how manufacturers, infrastructure managers, and other industrial operators capture, analyze, and act on data. In this comprehensive guide, we delve into what is industrial internet of things, explore real-world IIoT examples, and discuss the significant impact that IIoT is having on industrial operations globally.

This article explains the core components and benefits of IIoT, addresses the challenges of implementation, examines the rapidly growing market size, and details the architectural frameworks that support these systems. Moreover, it highlights the role of key vendors and platforms and explores how IIoT is shaping the future of roadway management. As industries face ever-increasing demands for efficiency, productivity, and safety, understanding IIoT stands for innovation and digital transformation has never been more important.

Understanding the Symphony of IIoT Components

To fully grasp what is industrial internet of things, we must first understand its building blocks. The IIoT ecosystem comprises several key components that work in harmony to transform raw data into actionable intelligence. This section explores the various elements that form the IIoT framework.

1. The Rhythm of Data Collection: Sensors

Sensors are the cornerstone of IIoT, acting as the eyes and ears of industrial operations. They continuously monitor and capture data on numerous parameters including:

- Temperature

- Pressure

- Vibration

- Flow Rates

- Humidity

Sensors answer the question what is IIoT by providing real-time insights into machine performance, operational efficiency, and environmental conditions. By continuously feeding data into the system, sensors ensure that industrial operations never remain in the dark.

2. Bridging the Divide: Connectivity

Once data is captured, it must be transmitted efficiently. Robust, industrial-grade connectivity solutions—such as Wi-Fi, cellular networks, and wired connections—ensure the seamless flow of data throughout the IIoT ecosystem. Reliable connectivity is vital for the effective operation of the industrial internet of things, maintaining a continuous dialogue between sensors, devices, and centralized platforms.

3. The Chorus of Devices: IIoT Devices

Beyond sensors, specialized IIoT devices such as smart controllers, gateways, and edge computing units play a crucial role in local data processing. These devices analyze data at the source (the “edge”), enabling real-time decision-making without complete reliance on central processing units. This distributed computing approach stands out among IIoT examples and showcases how industries can achieve faster response times and improved operational efficiencies.

4. Orchestrating the Data: IIoT Systems

At the core of the IIoT is the system that aggregates, processes, and analyzes data. These IIoT systems include:

- Cloud Platforms: Offering vast storage capacities and powerful analytics capabilities.

- Fog Computing: Processing data closer to where it is generated to reduce latency.

- Centralized Data Analytics Engines: Leveraging machine learning and artificial intelligence (AI) to derive actionable insights.

By coordinating these components, the industrial internet of things transforms raw sensor data into a symphony of information that drives informed decision-making across industries.

The Benefits of IIoT for Industrial Operations

The adoption of the industrial internet of things is not just a technological upgrade—it is a catalyst for digital transformation in the industrial sector. The benefits of IIoT extend far beyond improved connectivity and automation. Here, we discuss some of the most significant advantages that IIoT brings to industrial operations.

Boosting Productivity

Real-time data analytics is one of the most powerful drivers of productivity in modern industries. IIoT solutions enable:

- Predictive Maintenance: Machines can forecast their own maintenance needs, thereby reducing unplanned downtime.

- Optimized Production Lines: Continuous monitoring allows for dynamic adjustments to production processes, ensuring efficiency and minimizing waste.

- Automated Processes: Routine tasks can be automated, freeing up human resources for more strategic activities.

Many companies now ask what is IIoT and how it can help increase production throughput by integrating advanced sensors and analytics into their manufacturing lines.

Minimizing Downtime

Unplanned downtime can be catastrophic in industrial settings, leading to lost revenue and decreased customer satisfaction. IIoT’s predictive capabilities allow businesses to:

- Anticipate Equipment Failures: By monitoring machine health in real time, companies can schedule maintenance before breakdowns occur.

- Reduce Repair Times: Immediate alerts and diagnostics help technicians resolve issues more quickly.

- Ensure Continuous Operations: Enhanced monitoring means that even minor issues are detected early, ensuring uninterrupted production.

The answer to what is IIoT often lies in its ability to minimize downtime through predictive maintenance strategies and continuous monitoring—especially when leveraging innovative tools like LEOTEK’s upcoming LEOLINK products.

Unveiling New Operational Efficiencies

IIoT systems provide unprecedented visibility into every aspect of industrial operations. This data-driven approach enables:

- Resource Optimization: Identify and eliminate bottlenecks in production processes.

- Energy Efficiency: Monitor and adjust energy consumption in real time to reduce costs and environmental impact.

- Logistics and Supply Chain Management: Real-time tracking and analytics optimize inventory management and streamline supply chain logistics.

These benefits illustrate why many industries are adopting the industrial internet of things to achieve operational excellence and cost reductions.

Embracing the Fourth Industrial Revolution

The convergence of digital, physical, and biological technologies marks the Fourth Industrial Revolution (Industry 4.0), with the industrial internet of things at its core. By integrating IIoT into their operations, companies:

- Become More Agile: Quickly respond to market changes and customer demands.

- Enhance Innovation: Leverage data to drive new product development and process improvements.

- Stay Competitive: Maintain a technological edge in an increasingly digital world.

Thus, IIoT stands for not only connectivity and data analytics but also the strategic evolution of industrial enterprises into smart, interconnected systems.

Real-World Examples of IIoT Benefits in Action

To fully appreciate the transformative power of the industrial internet of things, consider these real-world examples where IIoT is making a significant impact.

Boosting Productivity

-

GE Aviation:

By integrating IIoT-enabled sensors into engine maintenance processes, GE Aviation reduced engine inspection times by 50%. This improvement accelerated turnaround times and increased aircraft availability. For more details, see GE Aviation’s overview of their capabilities (GE Aviation, n.d.) https://www.geaviation.com/. -

Honeywell Connected Aircraft:

Honeywell leveraged real-time engine data analysis to improve fuel efficiency by 3%, resulting in substantial cost savings for airlines. This case is a prime industrial internet of things example of how data analytics can enhance operational performance. More information can be found on Honeywell Aerospace’s connected aircraft solutions page (Honeywell Aerospace, n.d.) https://aerospace.honeywell.com/.

Minimizing Downtime

-

Rolls-Royce:

Rolls-Royce’s use of predictive maintenance technologies has prevented unplanned downtime in thousands of aircraft engines, saving airlines an estimated $1 billion annually. This case illustrates how IIoT ensures uninterrupted operations and reduces maintenance costs. Additional details are available from Rolls-Royce’s digital services page (Rolls-Royce, n.d.) https://www.rolls-royce.com/what-we-do/services/digital-services.aspx. -

Caterpillar:

By implementing remote monitoring and diagnostics, Caterpillar reduced unplanned equipment downtime by 20%. This example demonstrates how what is IIoT can be applied to heavy machinery and industrial equipment for enhanced reliability and performance. See Caterpillar’s technology and innovation page for more (Caterpillar Inc., n.d.) https://www.cat.com/en_US/support/technology.html.

Unveiling Operational Efficiencies

-

Schneider Electric:

Schneider Electric optimized energy consumption in their factories by 15% using smart sensors and real-time data analytics. This optimization reduced operational costs and minimized the environmental impact. More information can be found on Schneider Electric’s digital transformation page (Schneider Electric, n.d.) https://www.se.com/ww/en/work/campaign/innovation/. -

BASF:

BASF improved supply chain efficiency by 10% by leveraging IIoT for real-time tracking of goods and assets. Enhanced visibility provided by these systems allows for more effective inventory management and streamlined logistics operations. BASF’s digitalization initiatives are detailed on their website (BASF, n.d.) https://www.basf.com/global/en/who-we-are/innovation/digitalization.html.

Embracing Industry 4.0

-

Siemens:

Siemens transformed its Amberg facility into a fully digitalized, interconnected factory using IIoT. This revolution in manufacturing demonstrates how what is industrial internet of things can drive significant productivity gains and operational flexibility. Learn more about Siemens’ digital factory in Amberg (Siemens AG, n.d.) https://new.siemens.com/global/en/company/stories/industry/amberg-digital-factory.html. -

Foxconn:

Foxconn’s implementation of smart manufacturing solutions—including the integration of robots, sensors, and data analytics—greatly increased automation and production efficiency. This example serves as a prime illustration of IIoT industrial internet of things in a high-volume manufacturing environment. More information on Foxconn’s initiatives can be found on their website (Foxconn, n.d.) https://www.foxconn.com/.

These real-world examples clearly show the transformative power of IIoT and offer compelling industrial internet of things examples for companies seeking to boost productivity, minimize downtime, and achieve operational efficiencies.

The Challenges of Implementing IIoT

While the benefits of the industrial internet of things are vast, implementing these systems comes with its own set of challenges. Overcoming these hurdles is essential for organizations looking to fully leverage IIoT.

1. Connectivity in Harsh Environments

Industrial environments often present significant connectivity challenges. Factors such as:

- Interference from heavy machinery

- Physical obstructions

- Harsh weather conditions

can all impact the reliability of wireless and wired networks. Ensuring robust, secure connectivity remains one of the most critical challenges in deploying IIoT systems.

2. Data Security and Privacy

As industries adopt IIoT, they must confront the risk of cyberattacks. Protecting sensitive operational data involves:

- Implementing robust encryption protocols

- Establishing strict access controls

- Regularly updating security measures

These practices are essential to safeguard the industrial internet of things from vulnerabilities and potential breaches.

3. The Need for Skilled Personnel

Integrating and managing IIoT systems requires a workforce with specialized skills in data analytics, cybersecurity, and system integration. The shortage of qualified professionals can be a significant barrier to IIoT adoption, making investment in training and development crucial for long-term success.

4. Cultural and Organizational Change

Transitioning to an IIoT-based operation often requires a major cultural shift. Organizations must move from traditional, reactive methods to proactive, data-driven decision-making processes. Overcoming resistance to change and fostering an environment that embraces digital innovation are key challenges for many companies.

5. Interoperability and Standardization

With numerous vendors and platforms in the IIoT market, ensuring seamless integration between disparate systems is critical. The lack of standardized protocols can impede the smooth operation of interconnected devices and systems, necessitating flexible, interoperable solutions.

Addressing these challenges head-on is essential for organizations aiming to harness the full potential of the industrial internet of things and practically answer what is IIoT.

IIoT Market Size and Projections

The industrial internet of things market is experiencing rapid growth, with estimates from leading research firms illustrating its massive scale and potential. The following table summarizes key market data from various sources:

| Metric | Value (Year) | Source |

|---|---|---|

| Market Size | USD 321.81 billion (2022) | Grand View Research |

| Market Size | USD 394.0 billion (2023) | Grand View Research |

| Alternate Market Size Estimate | USD 320.9 billion (2022) | Precedence Research |

| Projected CAGR (2023-2030) | 23.2% | Grand View Research |

| Projected CAGR (2023-2032) | 17.2% | Precedence Research |

| Projected Market Size by 2032 | Up to USD 2,580.89 billion | Polaris Market Research |

These figures illustrate the significant expansion of the industrial internet of things market and underscore why understanding what is industrial internet of things is critical for future strategic planning.

Factors Influencing Market Growth

-

Regional Variations:

Asia Pacific is expected to be the fastest-growing region due to increased industrialization and supportive government policies. -

Industry Verticals:

Sectors such as manufacturing, oil and gas, transportation, and energy are key drivers of IIoT adoption. -

Technology Segmentation:

The IIoT market includes components such as sensors, connectivity solutions, cloud platforms, and analytics tools.

Understanding these figures and factors highlights why companies are increasingly asking what is industrial internet of things and how adopting these technologies can unlock significant competitive advantages.

IIoT Architecture and Solutions

A robust architectural framework is critical to the success of any industrial internet of things implementation. Typically, IIoT architecture can be visualized as a multi-layered model that ensures data is efficiently captured, transmitted, processed, and analyzed.

The Three-Layer IIoT Architecture

1. Edge Layer

-

Data Collection:

This layer includes all sensors and devices deployed in the field. These sensors capture critical operational data from industrial equipment, providing the raw inputs for the IIoT system. -

Local Processing:

Edge computing devices analyze data on-site, enabling immediate decision-making and reducing latency.

2. Network Layer

-

Data Transmission:

Data moves from the edge layer to centralized systems through various connectivity solutions, such as industrial-grade Wi-Fi, cellular networks, or wired connections. -

Security:

This layer implements robust security protocols to protect data during transmission.

3. Cloud/Fog Layer

-

Data Aggregation and Analysis:

Once data reaches cloud or fog computing systems, advanced analytics and machine learning algorithms process the information, resulting in actionable insights. -

Scalability and Storage:

Cloud platforms provide virtually unlimited storage and computational resources to manage large volumes of data.

Integration of Advanced Technologies

Modern IIoT solutions integrate additional technologies to enhance their capabilities:

- Artificial Intelligence (AI) and Machine Learning (ML):

These enable predictive maintenance, anomaly detection, and process optimization. - Digital Twins:

Virtual replicas of physical assets that allow simulation, testing, and enhanced decision-making. - Blockchain:

Enhances transparency and security in supply chain management by providing tamper-proof records.

Together, these elements form a comprehensive architecture that supports the complex needs of the industrial internet of things.

The Role of IIoT Vendors and Platforms

Successful deployment of IIoT systems depends on selecting the right vendors and platforms. The ecosystem is populated by a range of providers—from industrial giants to innovative startups—each offering unique solutions tailored to specific needs.

Leading Vendors in the IIoT Space

-

Industrial Giants:

Companies like General Electric, Siemens, Schneider Electric, Honeywell, and Bosch Rexroth have long-standing expertise in industrial systems and are at the forefront of industrial internet of things iiot solutions. -

Technology Leaders:

Major technology providers such as Microsoft, Amazon Web Services (AWS), IBM, and Cisco offer cloud and connectivity platforms that support IIoT applications. -

Specialized Startups:

Emerging players like PTC, ThingWorx, Software AG, and Hivemind bring innovative approaches to niche IIoT challenges.

Key Selection Criteria

When evaluating IIoT platforms, consider:

- Industry Expertise:

Does the vendor understand your specific industry needs? - Scalability:

Can the platform grow with your operations? - Security:

What measures are in place to protect your data? - Interoperability:

How well does the solution integrate with existing systems? - Openness:

Are there open APIs and standards to ensure flexibility?

These criteria help answer what is IIoT and how it can be seamlessly integrated into your existing infrastructure.

IIoT and Roadway Management: The Intertwined Future

The impact of the industrial internet of things extends far beyond traditional manufacturing. One area where IIoT is making a notable difference is roadway management. By leveraging real-time data and advanced analytics, cities and transportation agencies are revolutionizing how roads and traffic systems are managed.

Real-Time Traffic and Road Condition Monitoring

-

Sensor Integration:

Embedded sensors and cameras capture data on traffic flow, weather conditions, road surface quality, and ambient noise levels. This data is crucial for dynamic traffic management. -

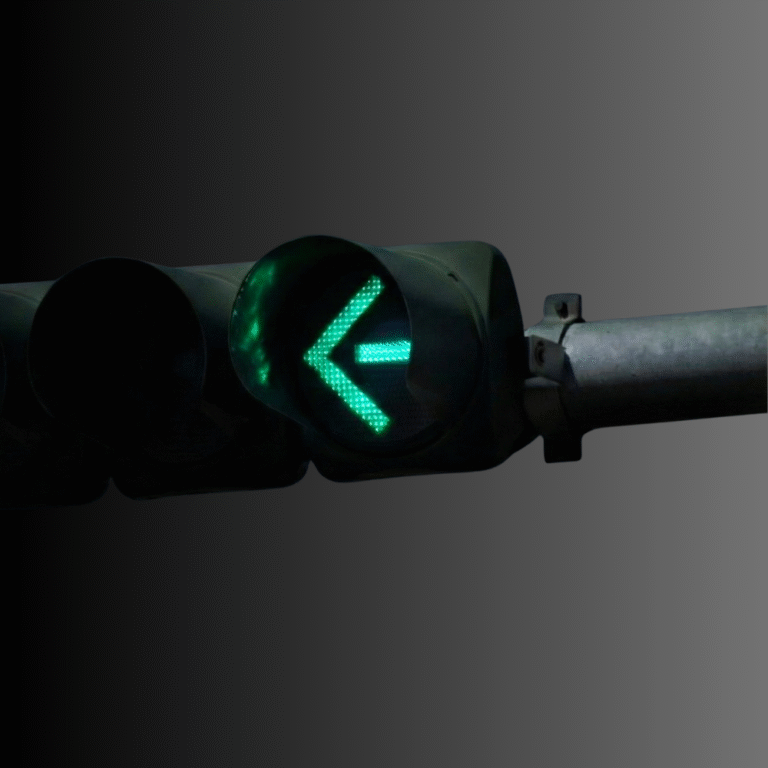

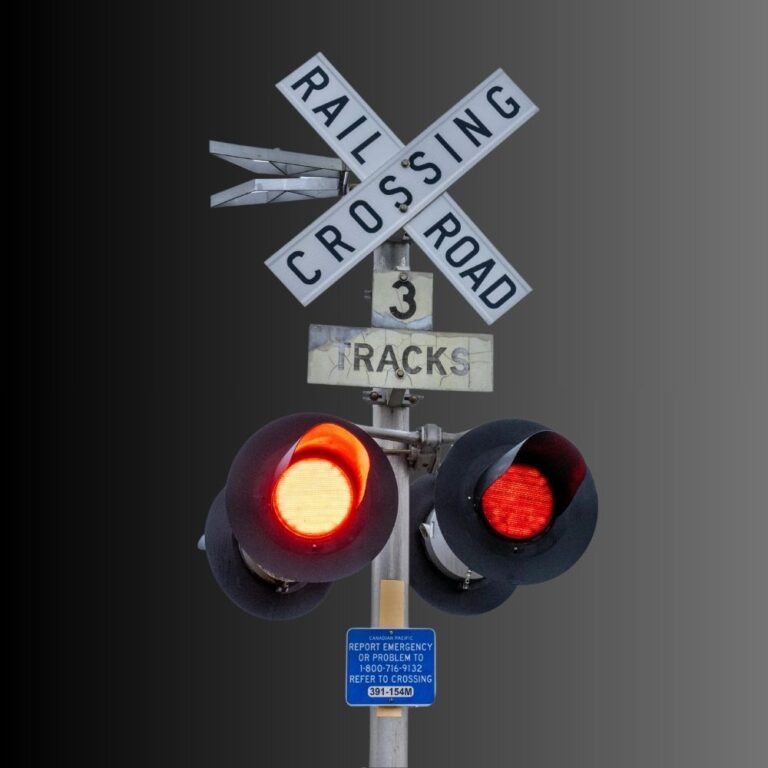

Connected Infrastructure:

Modern traffic signals, surveillance systems, and smart signage communicate with central systems to adjust signal timings, alert drivers to hazards, and optimize traffic patterns.

For example, LEOTEK’s upcoming KarbonCobra Series for smart LED light connectivity is designed not only for efficient roadway illumination but also for integrating advanced sensor networks. These sensors gather critical data, enabling dynamic traffic management and ensuring that every light contributes to a smarter, safer roadway environment.

Predictive Maintenance Through Smart Connectivity

A major breakthrough in IIoT is the ability to predict and prevent system failures. LEOTEK’s forthcoming LEOLINK products exemplify how lights data can be gathered and analyzed for predictive maintenance:

- Data Collection:

LEOLINK devices collect operational data from smart LED installations in real time. - Analytics:

Advanced analytics detect anomalies in performance, alerting maintenance teams to potential issues before they result in costly downtime. - Actionable Insights:

This proactive approach ensures that repairs are made swiftly, extending the lifespan of critical infrastructure and reducing operational costs.

By integrating KarbonCobra Series and LEOLINK solutions, roadway systems can achieve unparalleled reliability, turning everyday streetlights into intelligent nodes that contribute to predictive maintenance and overall smart city initiatives.

Deep Dive: Case Studies and Detailed Examples

In this section, we take an in-depth look at several case studies that highlight the practical benefits and applications of the industrial internet of things.

Case Study 1: GE Aviation – Redefining Maintenance

Overview:

GE Aviation implemented an IIoT solution that leverages sensor data to monitor engine performance in real time.

Key Benefits:

- 50% Reduction in Inspection Time:

Sensors collect critical performance data, enabling more efficient maintenance scheduling. - Increased Aircraft Availability:

Proactive maintenance minimizes unscheduled downtime.

Impact:

This case demonstrates how industrial internet general electric strategies can revolutionize maintenance practices, answering the question what is IIoT in a measurable way (GE Aviation, n.d.).

Case Study 2: Caterpillar – Smart Construction Equipment

Overview:

Caterpillar integrated remote monitoring and diagnostic systems into its construction equipment fleet.

Key Benefits:

- 20% Reduction in Unplanned Downtime:

Continuous monitoring ensures that potential issues are identified and addressed before causing major disruptions. - Enhanced Customer Satisfaction:

Improved equipment reliability leads to higher operational efficiency and client trust.

Impact:

This example serves as a robust IIoT industrial internet of things case study, showcasing how remote diagnostics can transform heavy machinery operations (Caterpillar Inc., n.d.).

Case Study 3: Schneider Electric – Optimizing Energy Consumption

Overview:

Schneider Electric used smart sensors and advanced analytics to monitor energy usage in its factories.

Key Benefits:

- 15% Energy Consumption Reduction:

Real-time data allowed for dynamic adjustments to energy usage patterns. - Cost Savings and Environmental Benefits:

Reduced energy consumption translated directly into lower operational costs and a smaller carbon footprint.

Impact:

This case reinforces the value of industrial internet of things iiot applications in achieving energy efficiency and sustainability goals (Schneider Electric, n.d.).

Case Study 4: Siemens – Digitalizing the Factory Floor

Overview:

Siemens transformed its manufacturing operations at its Amberg facility by fully integrating IIoT systems.

Key Benefits:

- Increased Production Flexibility:

Real-time analytics enabled rapid adjustments in production lines. - Enhanced Operational Efficiency:

The digitalized factory environment resulted in significant productivity gains.

Impact:

Siemens’ experience offers compelling IIoT examples of how smart factories can revolutionize production, positioning the company at the forefront of Industry 4.0 (Siemens AG, n.d.).

Additional Example: Foxconn – Industrial Automation

Overview:

Foxconn’s implementation of smart manufacturing solutions—including the integration of robots, sensors, and data analytics—greatly increased automation and production efficiency.

Impact:

This example serves as a prime illustration of IIoT industrial internet of things in a high-volume manufacturing environment (Foxconn, n.d.).

Future Trends and Innovations in IIoT

As the industrial internet of things continues to evolve, several emerging trends and innovations promise to reshape the landscape further.

The Rise of 5G and Beyond

- Faster Data Transmission:

5G networks will provide the high-speed connectivity necessary for real-time IIoT applications. - Enhanced Reliability:

Improved network reliability will support critical industrial operations and reduce latency.

Advances in Artificial Intelligence and Machine Learning

- More Accurate Predictive Analytics:

Continued advancements in AI will lead to even more precise predictions for maintenance and operational optimization. - Autonomous Systems:

Integration of AI with IIoT will pave the way for increasingly autonomous industrial systems, reducing the need for human intervention.

The Growing Importance of Cybersecurity

- Enhanced Security Protocols:

As cyber threats evolve, IIoT systems will incorporate more robust, adaptive security measures. - Blockchain for Data Integrity:

Blockchain technology will play a larger role in ensuring the integrity and traceability of industrial data.

Integration with Augmented Reality (AR) and Virtual Reality (VR)

- Training and Remote Assistance:

AR and VR technologies can be combined with IIoT data to provide immersive training experiences and remote support. - Digital Twins:

Enhanced digital twin models will allow for real-time simulations and troubleshooting, further improving operational efficiency.

Sustainable and Green IIoT Solutions

- Energy Efficiency:

IIoT systems will continue to drive innovations in energy management and sustainability, aligning with global environmental goals. - Smart Grids and Renewable Integration:

The integration of IIoT with smart grids will support the efficient use of renewable energy sources, reducing carbon emissions and operational costs.

These trends not only answer the question what is industrial internet of things but also forecast the dynamic evolution of the IIoT landscape.

Conclusion: Unleashing the Power of IIoT for a Smarter Industrial Future

The industrial internet of things (IIoT) is not merely a technological innovation—it is the linchpin of modern industrial transformation. By integrating advanced sensors, robust connectivity, edge computing, and cloud analytics, IIoT enables industries to operate more efficiently, reduce downtime, and drive sustainable innovation.

As detailed throughout this article, real-world examples from industry giants like GE Aviation, Caterpillar, Schneider Electric, Siemens, and Foxconn illustrate the tangible benefits of IIoT. Furthermore, as technologies such as 5G, AI, blockchain, and AR/VR continue to evolve, the potential for IIoT applications will only expand, opening new horizons for operational excellence and competitive advantage.

For those wondering what is industrial internet of things, the answer lies in its transformative power—a tool that not only optimizes current operations but also paves the way for the future of smart, interconnected industry. With a strategic approach that addresses connectivity, security, interoperability, and the need for skilled personnel, businesses can harness IIoT to redefine their operational capabilities.

Crucially, the future of smart industrial lighting is on the horizon with LEOTEK’s forthcoming product lines. The KarbonCobra Series is designed for smart LED light connectivity, integrating advanced sensors and connectivity features that enable dynamic control and data acquisition across urban and industrial environments. Simultaneously, LEOLINK products will transform how lights data is gathered, enabling predictive maintenance through real-time analytics. These innovations promise to enhance safety, reduce downtime, and extend the lifespan of critical infrastructure—exemplifying how next-generation IIoT solutions can drive a smarter, more connected future.

References

- Boyes, H., Günthner, S., Zwick, A., Chryssolouris, N., & Mavromati, V. (2017). The industrial internet of things (IIoT): Challenges, opportunities, and solutions. Computer, 50(1), 10–13.

- GE Aviation. (n.d.). Our capabilities. Retrieved from https://www.geaviation.com/

- Honeywell Aerospace. (n.d.). Connected aircraft solutions. Retrieved from https://aerospace.honeywell.com/

- Rolls-Royce. (n.d.). Predictive maintenance and digital solutions. Retrieved from https://www.rolls-royce.com/what-we-do/services/digital-services.aspx

- Caterpillar Inc. (n.d.). Technology and innovation. Retrieved from https://www.cat.com/en_US/support/technology.html

- Schneider Electric. (n.d.). Digital transformation in energy management. Retrieved from https://www.se.com/ww/en/work/campaign/innovation/

- BASF. (n.d.). Digitalization in industry. Retrieved from https://www.basf.com/global/en/who-we-are/innovation/digitalization.html

- Siemens AG. (n.d.). Digital factory: Amberg. Retrieved from https://new.siemens.com/global/en/company/stories/industry/amberg-digital-factory.html

- Foxconn. (n.d.). Innovation and automation. Retrieved from https://www.foxconn.com/

- Grand View Research. (2023). Industrial Internet of Things (IIoT) market size, share & trends analysis report. Retrieved from https://www.grandviewresearch.com/industry-analysis/industrial-internet-of-things-iiot-market

- Polaris Market Research. (2023). Industrial Internet of Things (IIoT) market analysis. Retrieved from https://www.polarismarketresearch.com/industry-analysis/industrial-internet-of-things-iiot-market

- Precedence Research. (2023). Industrial Internet of Things (IIoT) market size report. Retrieved from https://www.precedenceresearch.com/industrial-internet-of-things-market